Lamborghini Huracan

V10 FSI

THE MIHEL ENGINE OIL TECHNOLOGY

Technological advancements are rapidly changing the world around us. New discoveries and achievements revealed by scientists accompany us at every step, spanning across every field of science. Similarly, in the petrochemical industry, nano-engineering has firmly established itself due to its exceptional properties.

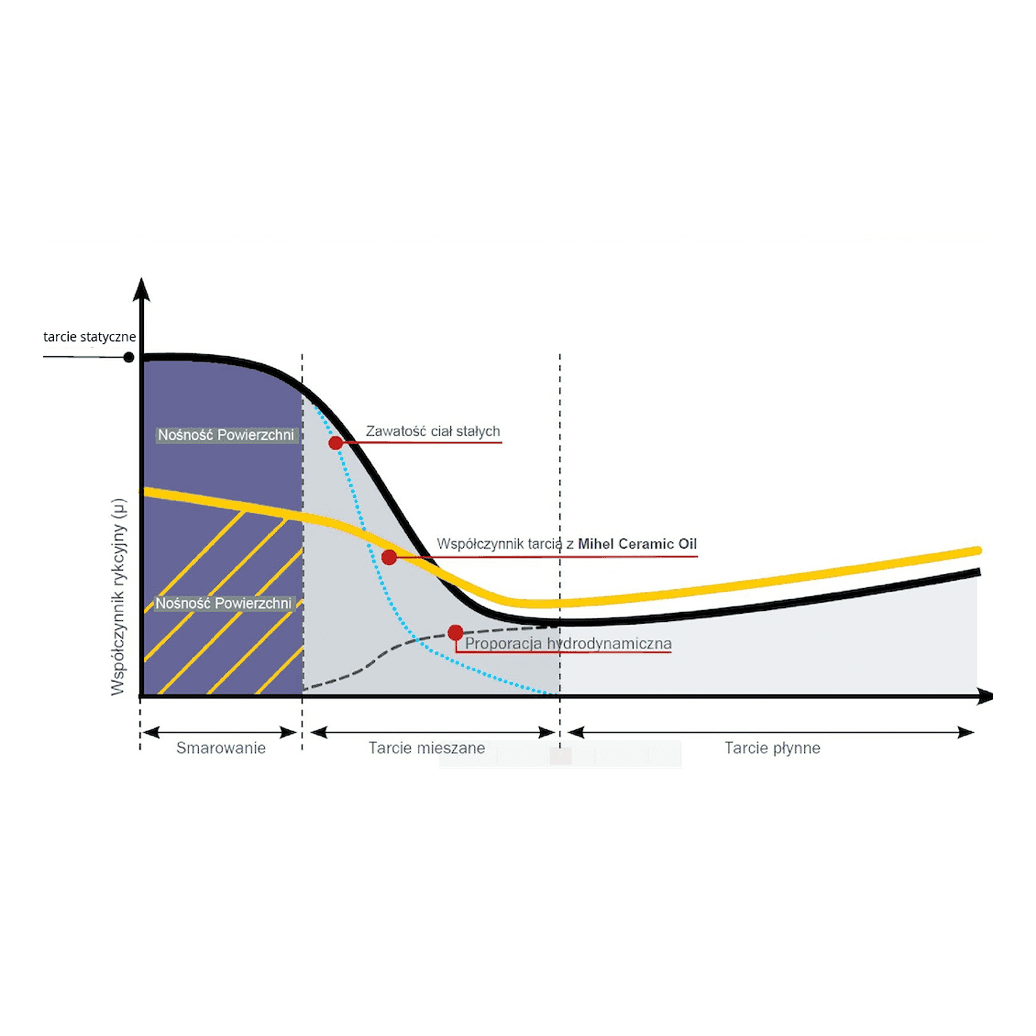

The NANO PROTECTION® technology, developed and utilized in MIHEL Ceramic Oil®, is the result of research seeking solutions for metal revitalization and reduction of friction coefficients. It represents progress in tribology, leading to the creation of a unique additive package. This additive, with its exceptional properties desired for lubricant characteristics, allowed the development of a top-quality oil with very high repair properties and parameters.

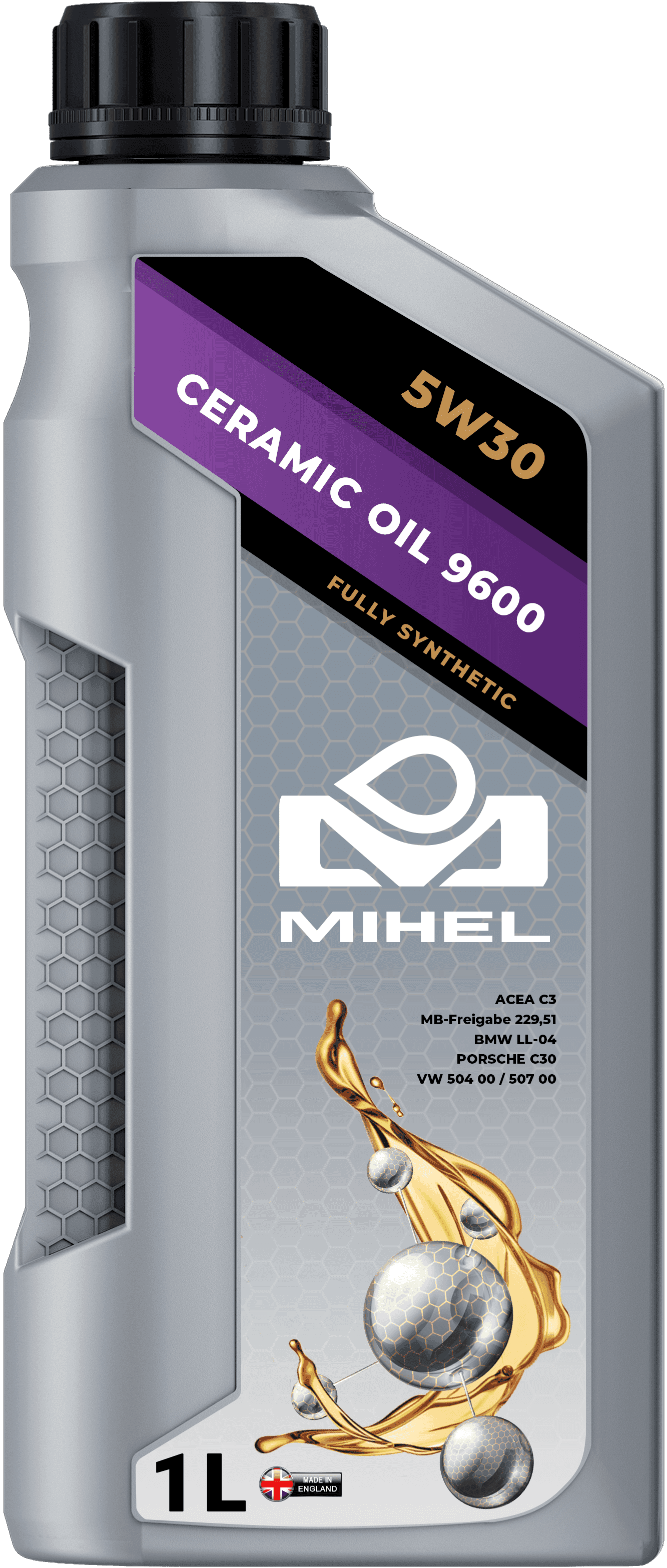

Our products are innovative engine oils based on PAO technology, enriched with ceramic nanoparticles. The unique crystalline structure of the included ceramics has documented achievements in reducing friction and engine component wear.

At MIHEL, we know that

How does it work?

Why choose it

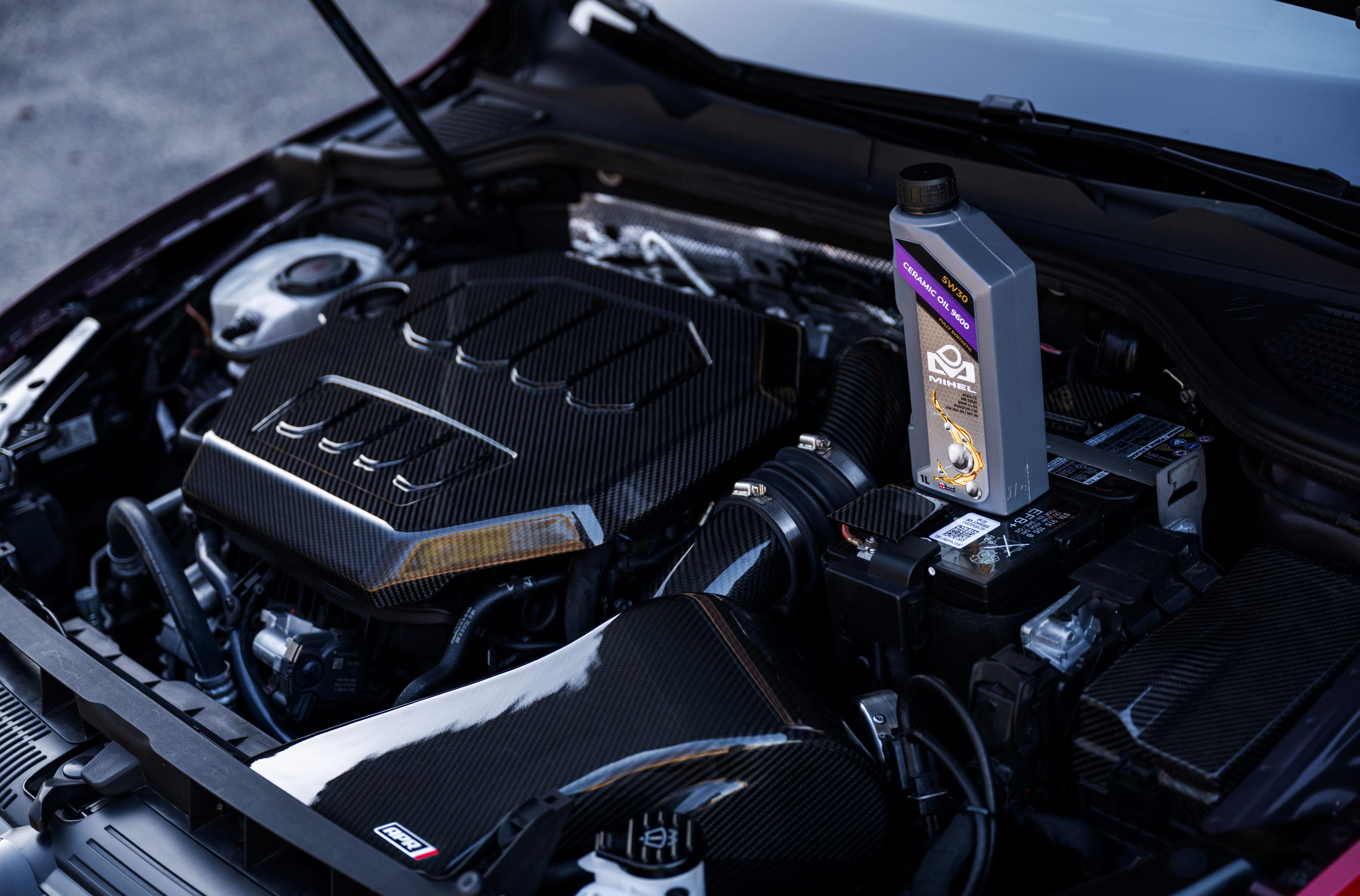

Our innovative product, MIHEL Ceramic Oil®, is a high-performance lubricant designed for a wide range of applications in passenger car engines and motorsports. It's utilized in high-performance power transmission systems, in extreme conditions requiring the most efficient lubrication and heat dissipation. The nano dispersion of ceramic particles in the oil is embedded in high-quality PAO oil with fine, crystalline hexagonal particles.

Using MIHEL Ceramic Oil® enhances the operation of mechanisms, thereby contributing to reducing their wear. The application of our oil sets new standards in performance and fuel efficiency. Its effectiveness is particularly noticeable in highly demanding lubrication conditions—especially when coupled with high temperatures, maximum loads, and high friction speeds.

Compendium of Knowledge

Society of Automotive Engineers

For example, in the name SAE 5W-40, the number before the letter W denotes the viscosity at low temperatures. The lower the value before the W, the more fluid the oil is at low temperatures. The number after the W signifies viscosity at high temperatures. The higher the "hot" viscosity, the more stress the oil can withstand at high temperatures. To avoid confusion when selecting engine and gearbox oils, viscosity classes for gearbox oils are also designated by SAE.

They describe the American requirements and criteria for classifying the quality of engine oils. The basic division here pertains to gasoline engines (oils marked with the letter "S") and Diesel engines ("C"). Always following the letter that indicates the type of engine, there's a second letter indicating the standard relevant to that operating fluid. Importantly, the further along the alphabet the letter is, the higher and newer the oil standard, and consequently, its class is better, e.g., SN > SL, SL > SG, CI > CS, and so on. Additionally, in the case of oils for diesel engines, sub-standards are distinguished following a combination of letters and specified in numbers, such as CF-2, CH-4, CJ-4.

When choosing oil for your car's engine, you can always select an oil with a higher standard and better parameters than those for which the engine was designed, but only within "adjacent" standards (e.g., SN oil instead of SM). Adding oil with a lower standard (weaker parameters), however, can lead to faster wear of components or even damage to the power unit. A similar effect can be achieved when adding oils that meet new standards to older units, for instance, SN oil instead of SG.

Since European operating conditions and engine characteristics significantly differ from American ones, the ACEA (Association des Constructeurs Europeens d’Automobiles) introduced its own oil classification system in 1996. It is based on the API classification system, focusing mainly on two aspects: requirements for lubricant properties and compliance with EURO emission standards. Additionally, it takes into account positive test results in defined European vehicle engines.

The current ACEA-2004 classification describes oils of various quality classes, where A (A1, A2, A3, A5) indicates oils for passenger cars with gasoline engines, B (B1, B2, B3, B4, B5) refers to oils for passenger cars with diesel engines, C (C1, C2, C3, C4) denotes engine oils with a low SAPS level, and E (E2, E6, E7) represents oils for heavy-duty vehicles with diesel engines.

Used by the most demanding users